4. CONDUCTOMETRIC TITRATIONS

Exp. 1. Determination of sulfates in drinking water

4.1. The chemistry of the system

A

large number of the analytical methods for determination of sulfates are based

on precipitation of BaSO4 or PbSO4. Gravimetric, turbidimetric

and various titrimetric techniques have been used.

The

determination of the sulfates in drinking water is based on a conductometric

titration, where sulfates are precipitated as BaSO4

![]()

The

precipitation process has been the subject of comprehensive studies. In respect

to a conductometric titration of sulfates in drinking water, the following

interferences have to be considered:

(i) coprecipitation of Ca2+ and

Mg2+;

(ii) precipitation of bicarbonates and

carbonates as BaCO3;

(iii) H+ interferes if the

indifferent anion of the titrant (Ba2+) is a weak acid.

To

overcome the interferences, an efficient pretreatment performed in an

ion-exchange flow system is used1.

The strategy

of the experiment in view of the above points:

1.

The interference of Ca2+ and other cations is overcome by replacing

them with another cationic species via a cation exchange resin. Desirable

cations are Li+ or Na+, however an intermediate step -

replacement to H+ - is taken in order to discard carbonates and

bicarbonates.

2.

As a result of the above step, the carbonates and the bicarbonates are

transformed to carbonic acid. Carbonic acid can be purged by i) boiling the

solution, ii) saturating the solution with a gas different than CO2.

A different, recently developed approach, based on thin-film gassing out, which

is both efficient and well adapted to flow processes, has been used.

3.

After discarding the interfering cations and anions, the solution contains

protons and the anions originally present in the sample, except for the

carbonic species. The protons are neutralized in order to enable the usage of

the titrant containing acetate as counter anion and also in order to reduce the

background conductance. The neutralization is normally carried out with a

pH-metric titration. In this experiment a different, more efficient and

well-adapted approach for a flow process is used: the protons are exchanged via

a cation exchanger to Li+ or Na+ ions.

4.2. Factors of importance in a

precipitation conductometric titration

·

In order to

obtain a sharp-angled conductometric titration curve it is advantageous to use

a titrant whose indifferent (counter) ion has a relatively low ionic

conductance (Fig.4-1). By consulting Table 1 the counter anion of the titrant

is chosen to be acetate.

Table 1. Equivalent Conductivity at Infinite Dilution at 250C

|

Cation |

|

Anion |

|

|

H+ |

350 |

OH- |

198 |

|

Li+ |

38.7 |

Cl- |

76.3 |

|

Na+ |

50.1 |

Br- |

78.4 |

|

K+ |

73.5 |

NO3- |

71.4 |

|

Rb+ |

76.4 |

CH3COO- |

40.9 |

|

Cs+ |

76.8 |

ClO4- |

68 |

|

|

|

½

SO42- |

80 |

The use of acetate anion pauses a restriction on the composition of the titrated solution: pH neutrality and absence of salts of weak acids or base are required. This, however, does not complicate the chemical pretreatment of the sample: the only salts of weak acids in drinking water are the carbonates and they are purged in step (2). The pH neutrality is desirable for other reasons as well as explained below and is performed in step (3).

·

The

solubility product of BaSO4 in aqueous solutions is

moderately low (~10-10) and determines the detection limit of the

titration. In order to reduce the detection limit of the method, the titration

is carried out in presence of high concentration of ethyl alcohol: 100-200% in

volume. The solubility product is strongly reduced in alcohol.

·

High

conductance background of the tested solution has two deteriorating effects:

(i) At low sulfate concentrations the

background conductance may be 100 times larger or more, compared to the

variation of conductance as a result of the titration. To solve this

problem a device for offsetting the conductance electric signal was designed. It

enables to offset the entire background conductance and subsequently carry out

the titration at an optimal sensitivity. (The electronical offset does not

change the actual conductance of the solution).

(ii) The conductance is affected by

temperature (2% per 0C). This variation of the conductance

may be of the same order of magnitude or larger than those of the titration. In

most cases the temperature variations are constant during a single titration.

It is strongly advised to reduce the background conductance as much as

possible. This is the reason that in step (3) of the experiment all cations are

exchanged to Li+ with the relatively lowest ionic conductance (Table

1).

·

The

kinetics of precipitation of BaSO4

is slow and dictates a slow rate of titration. A new form of titrant addition

is used - that of transferring the titrant with a low flow-rate pump. This

allows performing an automatic titration with titration rate of about 0.1 to

0.2 ml/min, rates usually unachieved with commercial piston burettes.

Fig.4-1 Conductometric

titration of sulfates with Ba2+ as titrant and Cl- and

OAc- as counter anions.

Sample: 5.00 ml 0.50 mM Na2SO4.

Medium: water + ethanol 1:1.

Titrant: 10 mM Ba2+, flow rate:

0.122 ml/min.

4.3. Description of experimental setup

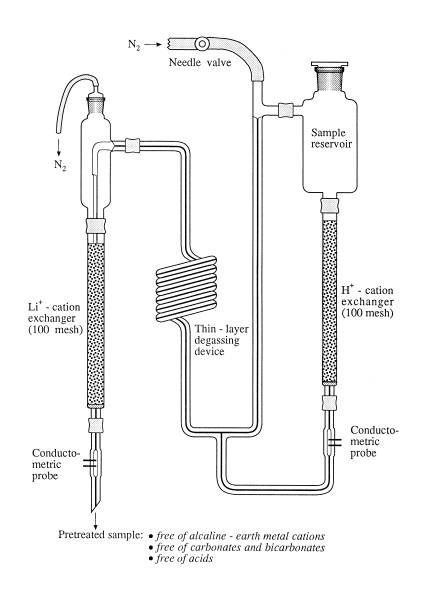

![]() Flow system for pretreatment of drinking water

Flow system for pretreatment of drinking water

The titration of sulfates is preceded by a

chemical pretreatment of the samples, described below:

|

Pretreatment of Drinking Water |

|||

|

Min+,

Xin-, HCO3- (Mi: Ca, Mg, Na, K, etc.) (Xi: Cl, NO3, SO4, etc.) |

|||

|

exchange of

cations by ion-exchanger in H+ form

|

|||

|

H+,

Xi-, H2CO3 |

|||

|

purging of CO2

by thin-layer degassing device

|

|||

|

H+,

Xi- |

|||

|

neutralization

by cation-exchanger in Li+ form

|

|||

|

Li+,

Xi- |

The pretreatment setup (Fig.4-2) consists of two cation exchange columns, a thin layer degassing device and conductometric probes for following the conductance during the elution step.

Fig.4-2 Ion-exchange

flow system for pretreatment of drinking water.

Dimensions of columns: length - 100 mm, ID

(H+ column) - 5 mm, ID (Li+ column) - 6 mm. Degassing

device: length of spiral - ~20 cm, ID - 0.7 mm. Conductometric probes (tungsten

wires): 0.5 mm diameter, 2 mm length.

Typical curves of conductometric titration of sulfates in tap water without and with pretreatment are shown in Fig.4-3.

Fig.4-3 Determination of sulfates in tap water.

Conductometric

titrations without and with pretreatment are shown. Water sample - 5.00 ml from

Tel-Aviv University. Medium - 50% ethanol. Titrant - 5.00 mM Ba(OAc)2,

flow rate 0.20 ml/min.

![]() Thin-layer degassing device. Purging of CO2

Thin-layer degassing device. Purging of CO2

The purging of CO2 is carried out

with the thin-layer degassing device2. The solution to be degassed

and an indifferent gas are mixed along a capillary tube (ID = 1 mm and length

30 - 60 cm). The pressure of the indifferent gas is ~0.3 bar, and the flow rate

is adjusted so that the solution is pushed uniformly to the walls of the

capillary, where an invisible thin film is formed. The intimate solution-gas

contact enables an efficient purging of the gas originally present in the

solution, in that case CO2. At the end of the capillary tube the

solution is CO2-free.

![]() Conductometric follow up of ion-exchange-column effluent

Conductometric follow up of ion-exchange-column effluent

The

in-situ measurement of the conductance of the effluent is an efficient tool for

optimizing the working conditions at ion-exchange columns. Several examples are

given:

(a) The conductometric probes at the exit

of the column can fulfill the simple task of indicating the end of the rinsing

stage following regeneration.

(b) In separation processes, it can be used

as a detector as in GC or HPLC.

(c) And finally, in our case, it enables to

follow the gradual changes occurring during the pretreatment of the sample

(cf., Fig.4-4). With the passage of the sample through the columns, the

conductance at the exit of each column increases from zero (the level of

distilled water) to a constant value. At the plateau the composition of the

effluent corresponds to that of the sample, in which all cations are replaced

by H+ or Li+, depending on the type of the column. The

conductance at the exit of the H+ column is higher than that of the

Li+ column, due to next factors: (i) the specific conductance of H+

is considerably higher than that of Li+, (ii) the concentration of

carbonic species at the exit of the Li+ column is equal to zero,

(iii) there may also be variation in the cell constants of the probes.

Fig.4-4 Conductance at column exits during pretreatment

Let

us consider the hypothetical situation, in which a very large volume of the

sample is passed through the columns. The capacity of the column surpassed, the

conductance at the exit of the H+ column would start to decrease and

that of Li+ column - to increase, until equality of specific

conductivity are obtained (explain!).

Typical follow up of the effluent

conductance is shown in Fig.4-4. During the elution the conductance at the end

of each column increases and reaches a plateau. (Explain the differences in

location and height of the two curves). The sample for the titration is

collected at the exit of the Li+ column when a constant value of the

conductance is reached.

![]() Estimation of the maximum volume of sample passed through the exchange

column

Estimation of the maximum volume of sample passed through the exchange

column

When

a quantitative ion-exchange process is required, the amount of sample to be

treated should correspond to not more than ~70% of the column capacity. The

type of ion-exchange process, the type of resin, the size of the resin

particles, the geometry of the column and the flow rate may strongly affect

that value. A rough estimation of the maximum volume of the sample can be made,

if the total concentration of the ionic species is approximately known.

Measurement of the specific conductance, k, of the sample provides an estimate of the total ionic concentration.

Assuming an average equivalent conductivity, L, of 120 ohm-1·cm2·eq-1, the total ionic

concentration in mol/l is

![]()

The recording of the conductance at the output of the columns is an useful indicator of the functioning of the resin.

![]() Determination of the conductometric cell constants of the titration cell

and the ion-exchange columns

Determination of the conductometric cell constants of the titration cell

and the ion-exchange columns

Although not imperative, the knowledge of the cell constants is helpful. If not provided by the instructor, the cell constants may be measured as follows.

Rinse

the cell with a small amount of 1.00 mM KCl. Fill the cell with the same

solution. Measure the conductance. The cell constant is calculated from: kcell

= L/k. The specific conductance, k, of 10 mM KCl at 200C is 1.278

mS/cm, with temperature coefficient 2.14%/K.

4.4. Experimental procedure

Chemicals

1. 1 M HCl

2. 1 M LiCl

3. 5.00 mM Ba(OAc)2

4. 0.5 mM Na2SO4

5. 0.5 mM Na2SO4 + 2

mM Ca(NO3)2

6. 0.5 mM Na2SO4 + 2

mM NaHCO3

7.

Ethyl alcohol

8. Strongly acidic cation exchanger Dowex

50W, 100-200 mesh, 3-5 meq/g dry material

9. 1 mM KCl (for calibration of

conductometric cell)

![]() Titration setup

Titration setup

Fig.4-5 Setup for conductometric titration of sulfates

![]() The regeneration of the ion-exchange columns

The regeneration of the ion-exchange columns

1. Disassemble the columns from the flow

system. Connect to each column a 15 ml reservoir. Connect the columns to a

conductometer. Set the sensitivity of the conductometer and the recorder, so

that the full-scale reading of the recorder is 0.2 S·cm-1.

Set the time scale to 1 cm/min. Start the recording device a few seconds before

the beginning of the regeneration process.

2. For the regeneration of the H+

column use ~10 ml of 1 M HCl and for the Li+ column use ~10 ml 1 M

LiCl. Pass the electrolyte through the resin, applying a small gas pressure to

obtain a flow rate of about 2 ml/min.

3. Rinsing of the columns: use small portions of water to wash the glass walls. If any water is present above the resin allow it to soak into before continuing the washing. Pass about 10 ml water until the conductometric reading drops to the level of the conductance of the distilled water. Compare the specific conductance and not the absolute value of conductance, due to the variety of conductivity cells you work with.

![]() Practicing with the flow system

Practicing with the flow system

In order to get acquainted with the flow pretreatment setup, you should operate it at first with distilled water. Starting conditions:

·

The pressure

of the gas (nitrogen) is adjusted to 0.4 bar. The needle valve is closed.

·

The level of

the liquid in the columns is equal to that of the resin.

·

The reservoir

stopper above the Li+ column is removed. Operating the flow system:

1. Fill the reservoir above the H+

column with distilled water. Place a 50 ml beaker beneath the Li+

column.

2. Slowly open the needle valve. Pressure

is applied on the column and the liquid starts flowing through it. Observe what

happens along the glass helix. At slow flow rates solution and gas are

interlaced. Increase further the flow rate of the gas. The glass capillary

seems to be empty. A thin, invisible film is formed along the capillary. These

are the suitable conditions for the operation of the thin-layer degassing

device.

3. At that stage solution accumulates

above the resin of Li+ column. Place back the stopper of the

reservoir from this column. The solution starts to flow through the column.

Under steady-state conditions the level of the liquid above the Li+

resin should be equal to that of the resin. In order to reach this condition,

close for a short time the gas exit of the thin plastic tube, connected to the

stopper.

4. Estimate the flow rate of the solution at

the exit. If it is lower than 1 ml/min, increase further the gas flow rate. If

solution accumulates in the reservoir of the Li+ column, you need to

increase the flow rate of the solution through that column. First discard the

excess of liquid as described above. Then prolong the plastic tubes for the

outlet of the gas. This increases the pressure applied on the column and so

increases the flow rate. Pay attention that this change did not affect the flow

through the helix capillary. If everything is O.K., you are ready for the real

experiment. Release the pressure by closing the needle valve and open the

stopper above the Li+ column.

![]() Pretreatment of the sample with the flow system

Pretreatment of the sample with the flow system

The

pretreatment of the sample for the determination of sulfates is carried out in

the above flow system. A relatively large amount (up to 30 ml) of a sample can

be introduced through the columns. The front of the sample pushes down the

distilled water, which originally fill the columns. The sample undergoes the

changes described in this chapter, section 4.3. Conductometric probes, located

at the exit of the flow system, are used to follow the progress of the elution.

The conductance changes from that corresponding to distilled water to that of

an effluent with uniform concentration (Fig.4-4). The effluent with uniform

concentration is collected for further analysis. The concentration of the

sulfate in this fraction is identical to that of the original sample.

It

is assumed at that stage that the gas pressure and flow rate of the gas are

adjusted in the previous steps. Check that the level of the liquid in both

columns is equal to that of the resin. Use the conductometric detectors to

ensure that the columns have been thoroughly washed with deionized water.

Place

a 10 ml graduated flask under the outlet. Prepare a 50 ml dry plastic beaker

for collecting the sample. Disconnect the reservoir of the H+ column

and replace it with a dry one, or rinse the original reservoir with a small

volume of the sample to be analyzed. Connect the conductometric probes to a

recording device. Set the sensitivity of the recorder to 100 mS full scale and use a time scale of 500 s.

Introducing

the sample in the flow system. The sample should be introduced at first

in small amounts into the column in order to replace the distilled water

without diluting the sample, located above the resin. Transfer with a Petri

pipette few drops of the sample directly above the H+ column. Apply

a pressure above the column for a short time. Let the solution be absorbed into

the resin. Repeat several times the sequence of addition small amounts of

sample and applying pressure. At that stage there is no more danger of diluting

the sample. Fill the container with about 20 ml of sample. Open the needle

valve. If the setting of the pressure and the flow rate of the gas have been

adjusted correctly in the previous section, the flow rate of the effluent

should be about 1 ml/min, the glass column is free of visible motion of

solution and there is no accumulation of solution above the Li+

column. If not, there is still time to make last adjustments.

Observe

the variation of the conductance at the exit of the flow system. After about 4

ml of solution has passed the column, the reading should be constant with time.

At that point start collecting the effluent for further use. After the required

volume of effluent is collected, close the gas valve. The flow system is ready

for further use if needed.

At the end of the experiment rinse the flow system with distilled water.

![]() Conductometric titration of SO42- with Ba2+

Conductometric titration of SO42- with Ba2+

Transfer

2.00 to 5.00 ml of the pretreated sample into the conductometric cell. Add

ethanol according to the concentration of sulfate in the sample:

for

[SO42-] < 0.5 mM, Vethanol/Vsample

= 1.5;

for

[SO42-] < 0.5 mM, Vethanol/Vsample

= 1.

The total height

of the liquid in the cell should be such that the electrodes are covered, also

when the solution is stirred. The time needed to reach the end point should be

no shorter than 2 minutes. Faster rate of titration may result a delay of the

end point, due to the slow kinetics of precipitation. The concentration of the

titrant Ba(OAc)2 is about five to ten times larger than that of the

sulfate in the original sample.

Get

the recording device ready. Dip the tube filled with the titrant into the cell.

Start the titration by turning on the pump. The titration curve is displayed.

At the end of titration turn off the recording device and the pump.

Repeat

the titration to check the reproducibility.

Titrate

the unpretreated drinking water sample under identical conditions. Refer to the

differences.

Determine

the flow rate of the pump as described in Titrimetric Methods of Analysis,

section 1.6. Report the concentration of sulfate in mmol/l and ppm SO42-.

![]() Effect of interferences

Effect of interferences

You

are provided with three synthetic solutions:

(a) 0.500 mM Na2SO4

(b) 0.500 mM Na2SO4

and 2 mM Ca2+

(c) 0.500 mM Na2SO4

and 2 mM HCO3-

Titrate each solution in presence of ethanol. Discuss the results.

![]() Effect of ethanol concentration

Effect of ethanol concentration

Titrate 5.00 ml of 0.500 mM Na2SO4 using different volume ratios of sample:ethanol (1:1.5, 1:1 and 1:0.5). Discuss the results.

References

1.

E. Kirowa-Eisner, D. Tzur, M. Brand and Ch. Yarnitzky, Microchem. J.,

61, 40(1999).

2.

Ch. Yarnitzky, Electroanalysis, 2, 581(1990).

Exp.2. Conductometric titration of strong and weak acids

Chemicals 1. HCl: 0.1, 1, 10 mM

2. HAc: 1, 10, 100 mM

3. NaOH: 1, 10, 100, 1000 mM

4. 1 mM KCl (for calibration of conductometric

cell)

Electrodes

For precision measurements of conductance platinized-platinum electrodes are used to reduce the polarizing effect of the passage of the current between the electrodes. For the purpose of conductometric titrations, where the end point is to be precisely determined, but the absolute conductance is of lesser importance, other electrodes may be used (bright platinum, tungsten and others).

Titration setup

The titration is performed with continuous addition of titrant using an automatic burette or positive displacement pump or peristaltic pump (cf., Fig.4-5). Viton or tygon tubing (I.D. about 1 mm) are recommended for the peristaltic pump. Read Titrimetric Methods of Analysis, section 1.6 for details of using automatic titrators. Determine the flow rate if a pump is used.

Procedure

1. Determine the conductometric cell

constant as described in Exp.1 of this chapter (Determination of sulfates in

drinking water).

2. Introduce 5.00 ml of acid sample into

the conductometric cell. Titrate with NaOH at a flow rate of 0.8 - 1.2 ml/min.

Perform a series of titrations according to the order and the conditions

summarized in the Table below. Data should be collected for up to 100% excess of

titrant.

3. Plot the graphs and determine the end

point. Refer to the shape of the titration curves. Compare with the

potentiometric titration curves.

4. Calculate the concentrations of the

acids in mol/l.

5. At the end of the working session rinse the pump tube, the cell and the beakers with distilled water.

|

Analyte |

Titrant (NaOH), M |

Maximal conductance* |

|

10-1

M HAc |

1 |

25 mS |

|

10-2

M HCl |

10-1 |

5 mS |

|

10-2

M HAc |

10-1 |

2.5 mS |

|

10-3

M HCl |

10-2 |

0.5 mS |

|

10-3

M HAc |

10-2 |

250 |

|

10-4

M HCl |

10-3 |

50 |

*For conductivity cell with a cell constant

of about 1 cm-1.

Recommended

Literature

A. I. Vogel, Textbook of Quantitative

Inorganic Analysis.

Go to Main Page