Electrolyzer Powered FID

The Gas Cylinder Free FID and GC-FID

Aviv Amirav, Nitzan Tzanani and Gad Frishman (July 2015)

Our Vision

Provide a new type of flame ionization detector (FID) that:

1. Eliminates all the gas cylinders

from the FID, while retaining all its features that made FID the GC industry

standard detector.

1. Eliminates all the gas cylinders

from the FID, while retaining all its features that made FID the GC industry

standard detector.

2. Lowers the price of GC purchase

for newcomers to GC and new laboratories through the elimination or major

reduction in the cost of needed gas supply system.

2. Lowers the price of GC purchase

for newcomers to GC and new laboratories through the elimination or major

reduction in the cost of needed gas supply system.

3. Saves gases and maintenance cost

more than the price of the GC in its lifetime.

3. Saves gases and maintenance cost

more than the price of the GC in its lifetime.

4. Frees precious laboratory space

occupied by gas cylinders and their service path.

4. Frees precious laboratory space

occupied by gas cylinders and their service path.

5. Considerably simplifies the purchase

and installation of GC-FID.

5. Considerably simplifies the purchase

and installation of GC-FID.

6. Simplifies GC-FID maintenance

and make it much easier to use.

6. Simplifies GC-FID maintenance

and make it much easier to use.

7. Enables a new dimension of GC-FID

transportability.

7. Enables a new dimension of GC-FID

transportability.

8. Is slightly more sensitive than

the standard FID.

8. Is slightly more sensitive than

the standard FID.

9. Is the safest FID in the industry.

9. Is the safest FID in the industry.

10. Enables full gas cylinder free

GC-FID operation for gases, VOCS and breath analysis applications.

10. Enables full gas cylinder free

GC-FID operation for gases, VOCS and breath analysis applications.

11. Provides all the above benefits

with ZERO added cost.

11. Provides all the above benefits

with ZERO added cost.

The Innovation and New Concept

A flame ionization detector (FID) was slightly modified and operated with a combustible gas mixture produced by simple water electrolysis, without gas separation or compression (USA, Israel and European and Japan Patents [1-3]). Our Electrolyzer powered FID (EFID) is based on the combustion of a premixed, stochiometric, hydrogen and oxygen gas mixture, at a low flow rate, without He make-up gas. The FID minimal modifications include the use of a small diameter flame tip, which is available by some FID vendors and the heating of the FID gas exit to a temperature above 100C (200C base temperature of the Varian FID). Our small water electrolyzer has a diameter of 66 mm, a height of 112 mm and loaded weight of 450 grams (beverage can size). This electrolyzer typically requires 1.5 Ampere at 2.4 Volts (3.6 Watts), consumes 12 ml water per day and enables 8 days of continuous operation. We have also developed a sophisticated, yet simple to construct and operate electrolyzer, which is most suitable for laboratory GC-EFID operation. Our laboratory electrolyzer requires only water, with no drying material, and enables full EFID automation for years of unattended operation. The water electrolyzer can be fully integrated with the GC and replace the FID three channels electronic flow control, thereby without added cost. The EFID efficiency is about 60 milliCoulomb/gram C and its detection sensitivity is superior (x3) to that of the Agilent or Varian FID, even when operated with zero grade gases. The EFID shows close to uniform carbon response with linear dynamic range of six orders of magnitude.

The Electrolyzer powered FID

We have extensively studied the EFID and fully tested it in combination

with a Hewlett-Packard 5890-II GC, Varian 3400 and 3800 GCs [4, 5] with our

home made Micro GC-EFID [6] and with the Chemito (now Thermo) Ceres 800

plus GC. The EFID basically performs like the FID as

a carbon selective detector with the FID known robustness, high sensitivity,

fast response, broad linear dynamic range, ease of use, excellent reproducibility

and high temperature operational range, which made it the GC industry standard

detector of choice. The EFID electrolyzer was fully debugged and extensively

tested in the last eight years.

Since our water electrolyzer contains no moving parts and does not perform

any gas separation or compression, it is a very reliable device, in contrast

to the various hydrogen gas generators.

Yet, its major attribute is that its added cost should be zero since it replaces the three channels electronic flow control of the FID.

Our EFID is operated with water only (water in, water out, and a little energy in between), without any external gas source. While its added cost should be practically zero it eliminates the need of gas cylinders, pressure regulators, gas purifiers, cylinder carrier, gas tubing, gas lines, tubing connectors, gas leak detector, gas purchase order forms and hydrogen safety requirements. Furthermore, no time should be devoted to frequent gas cylinder purchase, acceptance, storage, replacements, gas pressure regulator purging and leak detection.

Gas Cylinder Free GC-FID ("GasFree" GC)

We have utilized the EFID water electrolyzer for achieving complete freedom from all the GC gas cylinders [6]. The concept of electrolyzer operated GC-EFID is based on the use of the electrolyzer produced oxygen and hydrogen gas mixture consecutively for sample desorption and sweeping in a purge and trap sampling system, as the analytical column carrier gas and as the only required EFID combustible gas mixture. We found, like others, that standard columns with dimethyl polysiloxane adsorption film could be operated with oxygen up to 180C. A styrene-divinylbenzene based PoraBOND porous layer open tubular column was used for the GC separation, and we found that it could be operated up to 140C with the electrolyzer produced hydrogen and oxygen gas mixture. The gas cylinder free system operation was demonstrated with fast chromatographic separation (under one minute total analysis time) of acetone, ethanol, isoprene, dimethylfurane, benzene and toluene with a detection limit below 1 ppb. The capability of exhaled human breath analysis for industrial hygiene and medical diagnostic applications was studied and demonstrated [6]. An additional capability of fast total hydrocarbon content in air analysis was also explored.

Summary of EFID Features and Benefits for GC Vendors and Users

“Once two or more products are offering adequate performance, customers will find other criteria for choosing. These criteria tend to move toward reliability, convenience and price, all of which are areas in which newer technologies often have advantages.”

C. M. Christensen “The Innovator’s Dilemma” HarperCollins Publishers, New York 2000.

This section lists the various features, advantages and benefits of the EFID and explains why the EFID could be the best and most cost effective GC project, and thus, deserves the highest GC project priority by all GC vendors [7].

1. Summary of the EFID Product. Electrolyzer FID (EFID) is based on the operation of the

FID, with minimal or no modification, with a low flow rate of hydrogen and

oxygen gas mixture. This gas mixture is provided from a simple water electrolyzer,

without any gas separation or compression. The water electrolyzer provides

the full gas needs of the FID and eliminates the need for hydrogen, air and

helium make up gases. Thus, it is the lowest cost, smallest size, lowest

water consumption and most reliable FID gas supply system. The FID operation

is unchanged and its sensitivity is even slightly improved due to higher

(x3) flame chemical ionization yield.

1. Summary of the EFID Product. Electrolyzer FID (EFID) is based on the operation of the

FID, with minimal or no modification, with a low flow rate of hydrogen and

oxygen gas mixture. This gas mixture is provided from a simple water electrolyzer,

without any gas separation or compression. The water electrolyzer provides

the full gas needs of the FID and eliminates the need for hydrogen, air and

helium make up gases. Thus, it is the lowest cost, smallest size, lowest

water consumption and most reliable FID gas supply system. The FID operation

is unchanged and its sensitivity is even slightly improved due to higher

(x3) flame chemical ionization yield.

2. Cost of Purchase.

The added price of the water electrolyzer

of the EFID could be zero. This

unique feature emerges from the fact that the water electrolyzer acts as an

electronic flow control (EFC) through the regulation of the electrolysis current,

and thus replaces the three channels EFC of the FID. On the other hand, the

GC customers and users will save the cost of gas related items such as gas

cylinders, pressure regulators, gas purifiers, gas lines, tubing and tubing

connectors, compliance with hydrogen safety requirements, gas cylinder carrier,

etc.

2. Cost of Purchase.

The added price of the water electrolyzer

of the EFID could be zero. This

unique feature emerges from the fact that the water electrolyzer acts as an

electronic flow control (EFC) through the regulation of the electrolysis current,

and thus replaces the three channels EFC of the FID. On the other hand, the

GC customers and users will save the cost of gas related items such as gas

cylinders, pressure regulators, gas purifiers, gas lines, tubing and tubing

connectors, compliance with hydrogen safety requirements, gas cylinder carrier,

etc.

3. Cost of Maintenance.

The saving of gases with the EFID could

easily be more than the price of the GC in its lifetime.

3. Cost of Maintenance.

The saving of gases with the EFID could

easily be more than the price of the GC in its lifetime.

4. Small Footprint. The reality of a GC laboratory

is that the gas supply system is considerably bigger than the GC itself and

it also requires compliance with safety regulations and open space for cylinder

replacement. The EFID can

be fully integrated into any standard GC. Thus, having an integrated EFID could considerably reduce

the occupied gas supply space.

4. Small Footprint. The reality of a GC laboratory

is that the gas supply system is considerably bigger than the GC itself and

it also requires compliance with safety regulations and open space for cylinder

replacement. The EFID can

be fully integrated into any standard GC. Thus, having an integrated EFID could considerably reduce

the occupied gas supply space.

5. Ease of use. The EFID eliminates cylinder purchase

orders, acceptance, storage, replacement, leak checking and replacement downtime

and thus, with it, the GC-EFID

could be considered as much easier to use.

5. Ease of use. The EFID eliminates cylinder purchase

orders, acceptance, storage, replacement, leak checking and replacement downtime

and thus, with it, the GC-EFID

could be considered as much easier to use.

6. Ease of Purchase. Currently GC purchase and installation

is not easy and customers are required to make several purchase orders from

several vendors in order to prepare the gas supply system and comply with

the local safety requirements. The purchase of a GC with EFID will enable customers to have the

lowest cost GC and be served by a single vendor. The beauty of the EFID is that while the GC customers will

save, this saving is at the expense of other non-GC vendors.

6. Ease of Purchase. Currently GC purchase and installation

is not easy and customers are required to make several purchase orders from

several vendors in order to prepare the gas supply system and comply with

the local safety requirements. The purchase of a GC with EFID will enable customers to have the

lowest cost GC and be served by a single vendor. The beauty of the EFID is that while the GC customers will

save, this saving is at the expense of other non-GC vendors.

7. Safety. The EFID electrolyzer produces only 16

ml/min hydrogen, which is the lowest FID hydrogen flow rate in the industry.

This lower and thus safer hydrogen flow rate is fully electronically controlled

and any sensing of a flame out could automatically stop this low flow production.

No compressed hydrogen is produced and only minimal volume is available at

any time. Thus, the EFID

is the safest FID available.

7. Safety. The EFID electrolyzer produces only 16

ml/min hydrogen, which is the lowest FID hydrogen flow rate in the industry.

This lower and thus safer hydrogen flow rate is fully electronically controlled

and any sensing of a flame out could automatically stop this low flow production.

No compressed hydrogen is produced and only minimal volume is available at

any time. Thus, the EFID

is the safest FID available.

8. Sensitivity. The EFID sensitivity is slightly superior

to that of standard FID. However,

in contrast to standard FID it can be properly specified and its specification

could be easily met at the GC customer site since it does not depend on the

quality of gases provided on site, which could be poor/dirty, especially if a

new gas line is used, or in third world countries (gas quality issues). Furthermore,

high quality water is much easier to obtain than zero grade gases and thus

the EFID good sensitivity can last for the life of the GC.

8. Sensitivity. The EFID sensitivity is slightly superior

to that of standard FID. However,

in contrast to standard FID it can be properly specified and its specification

could be easily met at the GC customer site since it does not depend on the

quality of gases provided on site, which could be poor/dirty, especially if a

new gas line is used, or in third world countries (gas quality issues). Furthermore,

high quality water is much easier to obtain than zero grade gases and thus

the EFID good sensitivity can last for the life of the GC.

9. Gas Cylinder

Free GC. In applications such as LPG or petrochemical

gas analysis and process control the water electrolyzer can provide the full

gas needs of the GC, enable gas cylinder free GC-FID operation and provide

unique custom solutions for gas analysis and process control applications.

9. Gas Cylinder

Free GC. In applications such as LPG or petrochemical

gas analysis and process control the water electrolyzer can provide the full

gas needs of the GC, enable gas cylinder free GC-FID operation and provide

unique custom solutions for gas analysis and process control applications.

10. Hydrogen Generator Alternatives. Hydrogen generators

are now sold quite successfully and with growing numbers. This fact ensures

smooth penetration of the EFID and demonstrates its need. Hydrogen generators

are costly (over $5K), not very reliable and further require zero grade air

supply and helium make up gases (or the FID performance will suffer). It

is important to note that hydrogen cannot be used as a carrier gas for many important applications

such as pesticide, explosives and drug analyses due to its reactivity. This was clearly demonstrated in a few papers in the literature.

Even if the GC user wishes

to use hydrogen as a carrier gas and purchase a hydrogen generator, the EFID

is useful since it solves the issues

of zero grade air cylinders and eliminates the need for helium make up gas

with zero added cost.

10. Hydrogen Generator Alternatives. Hydrogen generators

are now sold quite successfully and with growing numbers. This fact ensures

smooth penetration of the EFID and demonstrates its need. Hydrogen generators

are costly (over $5K), not very reliable and further require zero grade air

supply and helium make up gases (or the FID performance will suffer). It

is important to note that hydrogen cannot be used as a carrier gas for many important applications

such as pesticide, explosives and drug analyses due to its reactivity. This was clearly demonstrated in a few papers in the literature.

Even if the GC user wishes

to use hydrogen as a carrier gas and purchase a hydrogen generator, the EFID

is useful since it solves the issues

of zero grade air cylinders and eliminates the need for helium make up gas

with zero added cost.

11. Cost Effective Fast Product Development. The EFID was developed in our laboratory and it is a fully

debugged product that requires only engineering and no R&D. The EFID was

licensed and developed as a product at Chemito (now Thermo).

11. Cost Effective Fast Product Development. The EFID was developed in our laboratory and it is a fully

debugged product that requires only engineering and no R&D. The EFID was

licensed and developed as a product at Chemito (now Thermo).

12. Competitive Advantage. The

EFID can increase the total GC market through the reduction of the cost of

analysis. It can also provide significant competitive advantage to the

vendor that will adopt it in view of its applicability and appeal to most

GC users. It requires the commercialization by a major GC vendor, since the

major benefits of zero added cost and full integration with the GC would

be lost with a small company.

12. Competitive Advantage. The

EFID can increase the total GC market through the reduction of the cost of

analysis. It can also provide significant competitive advantage to the

vendor that will adopt it in view of its applicability and appeal to most

GC users. It requires the commercialization by a major GC vendor, since the

major benefits of zero added cost and full integration with the GC would

be lost with a small company.

13. EFID Marketing.

The EFID can serve as the basis of a whole

GC marketing campaign. It possesses

a major appeal for a broad customer basis. It will uniquely enable its producer

to be a single vendor that will provide lower cost total solution and provide

all customer purchase and installation needs. The EFID features have major

appeal for newcomers to the world of GC and customers in third world countries.

Established laboratories should also seriously consider it for reasons of

gas cost saving, safety, intra-laboratory transportability and mostly in

order to eliminate the major inconvenience of gas cylinders handling. The

GC-EFID could enable live GC demonstrations at expositions and be offered

for a real “Test Drive” since it can be provided with a small helium cylinder

and does not require special preparations for its installation.

13. EFID Marketing.

The EFID can serve as the basis of a whole

GC marketing campaign. It possesses

a major appeal for a broad customer basis. It will uniquely enable its producer

to be a single vendor that will provide lower cost total solution and provide

all customer purchase and installation needs. The EFID features have major

appeal for newcomers to the world of GC and customers in third world countries.

Established laboratories should also seriously consider it for reasons of

gas cost saving, safety, intra-laboratory transportability and mostly in

order to eliminate the major inconvenience of gas cylinders handling. The

GC-EFID could enable live GC demonstrations at expositions and be offered

for a real “Test Drive” since it can be provided with a small helium cylinder

and does not require special preparations for its installation.

14. Customers Purchase Psychology. The EFID enables

the highest degree of GC-FID automation. It eliminates the periodic manual

cylinder purchase, acceptance, storage, replacement, gas purge cycles, leak

detection, and gas line and purifiers maintenance. Furthermore, the EFID

significantly improves the GC safety and saves gas purchase cost more than

the worth of the GC in its lifetime. How can we think in the 21 century,

at the era of mouse clicks, about manual handling of 80 Kilograms dangerous,

compressed and hazardous gas cylinders?

The elimination of gas cylinders and their involved manual labor

(inconvenience) will be the reason to purchase EFID while its gas saving

and improved safety will be the reasons given to the management.

14. Customers Purchase Psychology. The EFID enables

the highest degree of GC-FID automation. It eliminates the periodic manual

cylinder purchase, acceptance, storage, replacement, gas purge cycles, leak

detection, and gas line and purifiers maintenance. Furthermore, the EFID

significantly improves the GC safety and saves gas purchase cost more than

the worth of the GC in its lifetime. How can we think in the 21 century,

at the era of mouse clicks, about manual handling of 80 Kilograms dangerous,

compressed and hazardous gas cylinders?

The elimination of gas cylinders and their involved manual labor

(inconvenience) will be the reason to purchase EFID while its gas saving

and improved safety will be the reasons given to the management.

15. Product Differentiation. Gas chromatographs are now mature products and are

becoming closer to a commodity. The GC sales people need a real GC differentiator

that they can use in their sales speech. Since FID is the most widely used

GC detector, the EFID can enter their general sales speech in most sales

opportunities. Thus, we are fully convinced that it will be a self-selling

product and the EFID will lead the sale of the whole GC platform.

15. Product Differentiation. Gas chromatographs are now mature products and are

becoming closer to a commodity. The GC sales people need a real GC differentiator

that they can use in their sales speech. Since FID is the most widely used

GC detector, the EFID can enter their general sales speech in most sales

opportunities. Thus, we are fully convinced that it will be a self-selling

product and the EFID will lead the sale of the whole GC platform.

16. Market Penetration. A unique

marketing penetration strategy could be "Satisfaction guarantied or the EFID

will be replaced at no added cost with a FID" This means that the GC vendor

can promise to replace the electrolyzer with an EFC that costs about the same.

A dual EFID-FID configuration can also help its market entry. Another unique

marketing strategy could be to offer also a desk on wheels that is designed

to have the GC and accommodate a small helium cylinder for intra institute

or laboratory transportability. This way one can also guaranty delivery and

installation at the same day without any need for customer preparations.

16. Market Penetration. A unique

marketing penetration strategy could be "Satisfaction guarantied or the EFID

will be replaced at no added cost with a FID" This means that the GC vendor

can promise to replace the electrolyzer with an EFC that costs about the same.

A dual EFID-FID configuration can also help its market entry. Another unique

marketing strategy could be to offer also a desk on wheels that is designed

to have the GC and accommodate a small helium cylinder for intra institute

or laboratory transportability. This way one can also guaranty delivery and

installation at the same day without any need for customer preparations.

17. Environmental Friendly technology. These days our

world suffer from global warming and rising oil prices which also increase the

price of FID gases due to rising cost of cylinders transportation. The EFID will

eliminate those trucks that pollute our environment while delivering gases to GC

laboratory.

17. Environmental Friendly technology. These days our

world suffer from global warming and rising oil prices which also increase the

price of FID gases due to rising cost of cylinders transportation. The EFID will

eliminate those trucks that pollute our environment while delivering gases to GC

laboratory.

18. EFID Potential Impact on GC Sales. The EFID

addresses the needs of over 80% of the GC customers. It improves the GC ease

of use, make it safer, markedly lower its cost and cost of maintenance and

even lower its detection limit. Such a proposition should be hard to refuse

especially when it does not add to the cost of GC-FID purchase. Normally

it is considered that 1% cost reduction for a product in a mature market

such as GC can increase sales by 3% (but usually it reduces earnings by 3%).

Accordingly, the EFID can

potentially markedly increase the GC market share of the first company that

will sell it.

18. EFID Potential Impact on GC Sales. The EFID

addresses the needs of over 80% of the GC customers. It improves the GC ease

of use, make it safer, markedly lower its cost and cost of maintenance and

even lower its detection limit. Such a proposition should be hard to refuse

especially when it does not add to the cost of GC-FID purchase. Normally

it is considered that 1% cost reduction for a product in a mature market

such as GC can increase sales by 3% (but usually it reduces earnings by 3%).

Accordingly, the EFID can

potentially markedly increase the GC market share of the first company that

will sell it.

We all drive a car and about once a week enter a gas station and purchase gasoline. Clearly if we could have a water operated car with similar or better performance (and price) this could be a major reason to buy such a car. The GC-FID situation is similar, since the relative price of gases versus the GC is similar to that of gasoline versus the car. Similarly, the inconvenience of gasoline purchase is analogous to that of gas cylinder purchase for the GC. Accordingly, the EFID could serve as the basis of a GC-FID sales campaign and provide, as a new technology, a rare opportunity to significantly increase GC sales and market share.

Our EFID was developed and fully characterized on HP 5890 GC, Varian 3400 and 3800 GC’s on our home made “GasFree” Micro GC-EFID system and on the Chemito (now Thermo) Ceres 800 plus GC, and it can be demonstrated in our laboratory.

Naturally we are looking forward to collaborate with an interested major GC company.

References

1. A. Amirav and N. Tzanani

Flame-Based Method and Apparatus for Analyzing a Sample.

a) Israel Patent No. 115287.

b) USA Patent No 5741711 (1998).

c) Great Britain, Germany, France, Italy and The Netherlands, European

Patent 0763733.

d) Japan Patent Application 243300/1996 (approved and issued)

2. A. Amirav and N. Tzanani

Electrolyzer Device and Method for the Operation of Flame Ionization Detectors.

USA Patent No 6096178 (2000).

3. A. Amirav, G. Frishman and N. Tzanani

A Method and System for Gas Chromatography

Israel, USA, and Japan Patents.

4. Nitzan Tzanani and Aviv Amirav

Electrolyzer Powered Flame Ionization Detector

Analytical Chemistry 69, 1248-1255 (1997).

5. Nitzan Tzanani and Aviv Amirav

Electrolyzer Powered Nitrogen Phosphorus Detector

Field Analytical Chemistry and Technology. 1, 375-380 (1997).

6. Gad Frishman, Nitzan Tzanani and Aviv Amirav

Electrolyzer Operated Gas Cylinder Free GC-FID

Field Analytical Chemistry and Technology 5, 107-115 (2001).

7. Aviv Amirav

The Future of GC Detectors in the Era of Mass Spectrometer Detection

American Laboratory 33, 28-34 (2001).

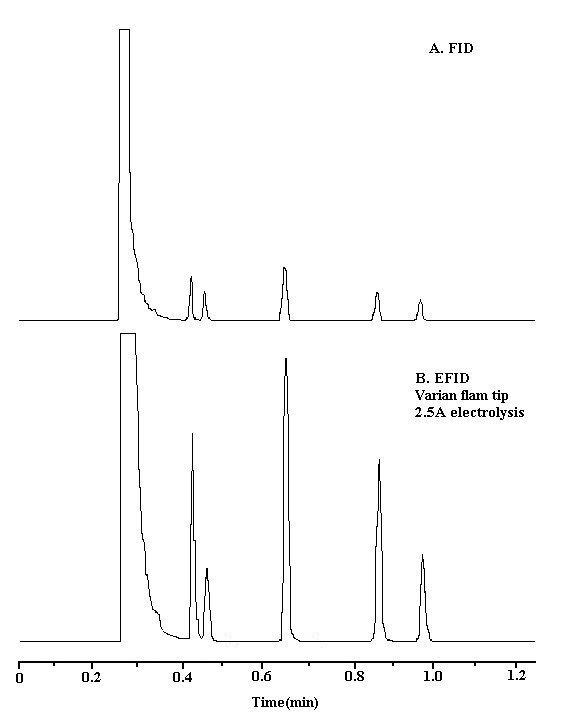

The chromatogram above was achieved without any FID gas cylinder and is compared with the same mixture analyzed with a standard FID using the same GC injection and short column conditions. 2.5 A water electrolysis current was employed, that produces 29 ml/min combustible gas mixture. Under these conditions, the EFID flame chemical ionization yield is about five times higher than that of a standard FID with its standard flame tip.

An EFID power point presentation is available on request.

For further EFID information, please contact me through my E-mail: amirav@tau.ac.il